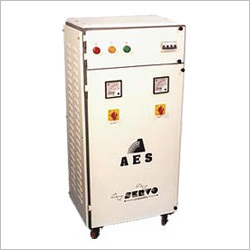

Three phase Servo Voltage Regulator

Price 1 INR/ Piece

Three phase Servo Voltage Regulator Specification

- Output Current

- Automatic adjustment as per load

- Input Voltage

- 300-470V (can be customized)

- Output Voltage

- 415V 1%

- Efficiency

- >98%

- Frequency (MHz)

- 50 Hz

- Phase

- Three Phase

- Rated Voltage

- 100 Watt (W)

- Current

- up to 2500 Amps (based on rated capacity)

- Weight

- Depending on Model (e.g., approx. 150-850 kg)

- Ambient Temperature

- -5C to +55C

- Control System

- Automatic

- Usage

- Industrial and Commercial Applications

- Insulation Resistance

- Better than 5 Mega Ohms

- Design

- Enclosed metallic cabinet, floor mounted

- Voltage Protection

- Under & Over Voltage Protection, Short Circuit & Overload Protection

- Display

- LED

- Dimension (L*W*H)

- as per capacity/model, e.g., 1400x1100x1700 mm

- Rated Power

- 10 kVA to 2000 kVA (customizable)

- Current Type

- AC

- Waveform Distortion

- Nil (No distortion)

- Product Type

- Three phase Servo Voltage Regulator

Three phase Servo Voltage Regulator Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 7 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About Three phase Servo Voltage Regulator

Inspired by the trust of our valuable patrons, we are continuously involved in manufacturing and exporting Three phase Servo Voltage Regulator. To offer clients with optimum functioning products , we manufacture these voltage regulators by making use of advanced technology. These are installed for different electronic devices to control fluctuating voltage outputs. We offer the Three phase Servo Voltage Regulator in different specifications to satisfy the variegated needs of clients.

Features:

- No wave form distortion

- Power efficient

- Easy to install

- Compact design

Reliable Voltage Correction in Demanding Applications

Designed for both industrial and commercial usage, this servo voltage regulator ensures consistent and distortion-free output (415V 1%) for sensitive equipment. Rapid correction speed and high efficiency (>98%) make it the choice for locations requiring dependable power management, especially where voltage fluctuations can damage machinery or disrupt processes.

Customizable and Robust Design Solutions

From air or oil cooling to transformer type selection (toroidal or roller), every aspect of this regulator is customizable according to your operational requirements. Its sturdy, enclosed metallic cabinet supports floor mounting in varied environments, and built-in protections safeguard against common electrical risks for long-term reliability.

FAQs of Three phase Servo Voltage Regulator:

Q: How does the Three Phase Servo Voltage Regulator maintain stable output voltage during power fluctuations?

A: This regulator monitors and adjusts voltage automatically at a correction speed of 35 V/sec, providing 1% output voltage regulation. Its servo control system and transformer technology ensure reliable performance, keeping output voltage steady even under variable input conditions.Q: What are the benefits of choosing air cooled versus oil cooled models?

A: Air cooled models are preferable for standard operating conditions and easier maintenance, while oil cooled variants are recommended for higher rated loads and environments with elevated ambient temperatures. The choice is model-dependent and tailored to your application needs for optimum cooling and longevity.Q: When should an isolation transformer be incorporated into the regulator system?

A: An isolation transformer is recommended when additional safety or electrical isolation is required, especially for protecting sensitive equipment from potential voltage spikes or ground loop disturbances. It is available on request for applications demanding enhanced protection.Q: Where is this voltage regulator typically installed, and what are its mounting options?

A: Designed for indoor industrial and commercial environments, the regulator features a floor standing configuration within an enclosed metallic cabinet. Dimensions and weight vary per model, allowing installation flexibility according to facility layout and power requirements.Q: What is the process for customizing rated power and input/output voltage specifications?

A: Customers can specify rated power (from 10 kVA up to 2000 kVA), input voltage (usually 300-470V, but customizable), and other functional options during procurement. The manufacturer provides technical guidance to ensure the regulator aligns with local electricity standards and operational demands.Q: How does the voltage regulator ensure the safety and reliability of connected equipment?

A: It incorporates under and over voltage protection, short circuit and overload safeguards, and delivers high insulation resistance (>5 Mega Ohms). These features help prevent equipment damage and support safe, continuous operation in high-load environments.Q: What types of display and monitoring systems are available with these regulators?

A: The regulator features an LED display for clear monitoring of operation status and output readings, enhancing user convenience and enabling quick identification of voltage irregularities for prompt troubleshooting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Servo Stabilizer Three Phase Category

Servo Stabilizer Oil Cooled

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Design : Rugged & compact design

Dimension (L*W*H) : As per capacity/model

Product Type : Oil Cooled Servo Stabilizer

Ambient Temperature : 0C to 50C

Aes Servo Stabilizer Three Phase

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Design : Floor Mount/Metal Cabinet

Dimension (L*W*H) : 900 mm x 550 mm x 1050 mm

Product Type : Aes Servo Stabilizer

Ambient Temperature : 0C to 45C

Servo Stabilizer oil Cooled kva With Builtin isolation Transformer

Minimum Order Quantity : 1 , , Unit

Frequency (MHz) : 50 Hz / 60 Hz

Design : Oil Cooled, Floor Mounted, Compact

Dimension (L*W*H) : Varies as per capacity (e.g., 1400 x 900 x 1600 mm)

Product Type : Servo Stabilizer

Ambient Temperature : 5C to +50C

Single Phase Servo Voltage Regulator

Minimum Order Quantity : 1 Unit

Frequency (MHz) : 50 Hz

Design : Compact, Floor Mount

Dimension (L*W*H) : 420 mm x 270 mm x 390 mm

Product Type : Single Phase Servo Voltage Regulator

Ambient Temperature : 0C to 45C

We mainly accept local inquiries.....

Send Inquiry

Send Inquiry